Temperature Resistance 3.0mm H13 Hepa Filter For AC Customized Size

Product Details:

| Place of Origin: | China |

| Brand Name: | LESITE |

| Certification: | CE |

| Model Number: | Hepa Bag Filter |

Payment & Shipping Terms:

| Minimum Order Quantity: | Negotiate |

|---|---|

| Price: | Negotiate |

| Packaging Details: | export packing |

| Delivery Time: | 5-8 DAYS AFTER DEPOSIT |

| Payment Terms: | T/T, L/C |

| Supply Ability: | 5000 m² per month |

|

Detail Information |

|||

| Thickness: | 2.5±0.5 Mm | Efficency: | 30±10 % |

|---|---|---|---|

| Size: | Customized Size | Material: | Fiber-glass |

| Condition: | New | Efficiency: | 99.97%, H13~H14 |

| Application: | Cleanroom | ||

| Highlight: | Temperature Resistance h13 hepa filter,3.0mm h13 hepa filter,h13 hepa filter for ac |

||

Product Description

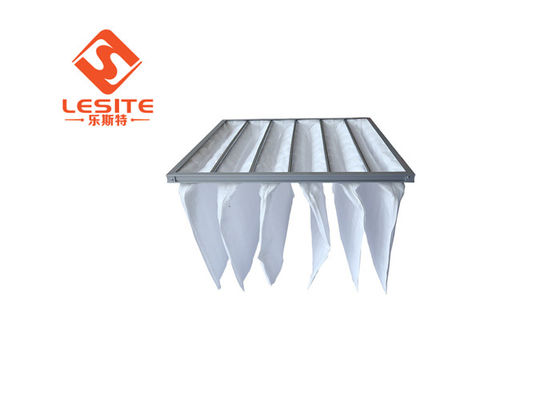

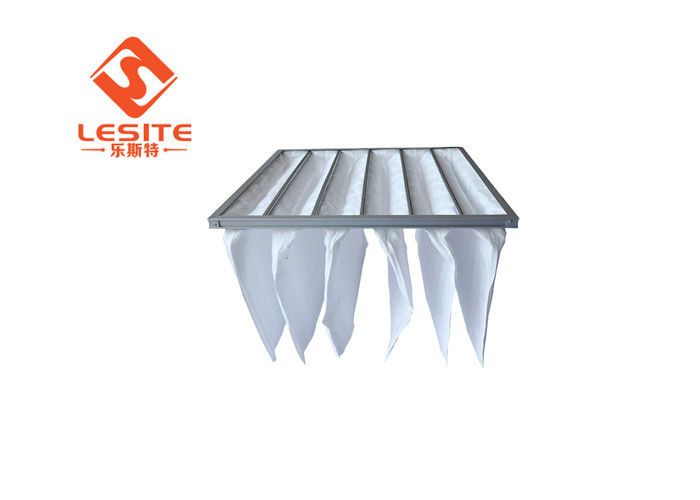

Hepa Bag Filter Thickness 2.5±0.5 Mm Micro-Fine Glass Fiber Can Resist The Temperature

Mini pleat HEPA filter mainly adopts thermal sol as dividers of filter element, is advantageous for the mechanized production, and it has small volume, light weight, easy installation, stable efficiency, the advantages of uniform wind speed in the clean equipment matching filter without clapboard structure is used in most hepa filter with no air shower pass box equipment filter efficiency H13:99.97 99.99% @ 0.3 microns.

Usage: used for medicine, vegetables, raw, marked finish machining and precision instruments, electronic instrument workshop purification equipment required, two, functions: air shower, clean workshop and form a complete set of the clean room equipment, when workers in workshop, through this equipment, with strong and clean air, remove the clothes and carry on the surface of the dust.

(1) installation of high efficiency filter:

As a result of the brittleness of glass fiber paper, so in the use and installation should first consider not to contact sharp objects and repeated rubbing, secondly, glass fiber paper should be used in contact with water or other corrosive liquid as far as possible, so as not to affect its normal use. Clean plant must have good cleaning equipment. Thirdly, the reasonable use of coarse, medium and high efficiency filter ensures that each filter does not bear heavy dust load. Visual inspection shall be carried out before installation to check whether the appearance of filter paper and filter is damaged, and the sealing condition shall be tested after installation to strictly detect leakage.

(2) common sense of high efficiency filter

For different particle sizes, the efficiency of the hepa filter can be up to 99.999999 (overseas). Some people equate the efficiency of a filter with the cleanliness of a clean room, and it seems like a hundred or even a ten can be achieved with as many as nine ultra-high performance filters. This is actually a misconception. Hepa filters are the heart of the system, but they are not the only guarantee of cleanliness. The efficiency of the hepa filter is only one of the necessary conditions, and it is also an easy condition to achieve. There are many other requirements to achieve a clean room grade, such as wind speed, air change times, door and window seals, and control of people entering and leaving the clean room. Only when all these aspects are up to standard can we guarantee the cleanliness of clean room.

(3)Hepa filters are mainly used to catch particulate dust and various suspended substances below 0.3um.

Air purifier is mainly composed of filter element and shell.

The basic requirements are high filtration efficiency, low flow resistance and continuous use for a long time to reduce the cost of consumables in the later stage.

Use made of super fine glass fiber paper, offset paper, aluminum membrane materials, such as partition board, with wooden frame aluminum alloy agglutination, the use of special silicone rubber, no smell, not surface hardening, long time also won't have crack, stable chemical performance, corrosion resistance, can absorb heat bilges cold shrink stress without cracking, moderate hardness, good elasticity.

Each unit is tested by sodium flame method, with high filtration efficiency, low resistance, large dust capacity and other characteristics.

High-efficiency and ultra-high-efficiency filters are used in the end of clean room, which can be divided into: high-efficiency with partition, high-efficiency without partition, high-efficiency with large air volume, high-efficiency filter and so on.

|

Product Name

|

F5 F6 F7 F8 Bag Type Filter

|

Style

|

Bag Type Medium Fiter

|

|

Brand

|

LESITE |

Colour

|

silvery

|

|

Advantages

|

waved screen has improved filtering area and dust collecting capacity

|

Place of Product

|

Guangdong Province,China

|

|

Usage

|

Widely used in primary air filters as a preferential choice for air purification

|

Modes of packing

|

Packed in Standard carton

|

|

Size

|

customized

|

After sale service

|

support

|